Rating is a very well known word for show business. It indicates most favorable shows and programs. It gives very precise idea to marketing people while preparing the ads. Besides this, rating defines the price rates of the ads. Why don’t we use it for material requirement planning?

I developed this method several years ago. We were preparing critical component lists for the suppliers on weekly basis (please look at my previous post “Preparing Critical Components List” to see its detail). Actually you know that which components are fall in critical level frequently by experience. However, it’s important to show this to your suppliers and your people as a fact.

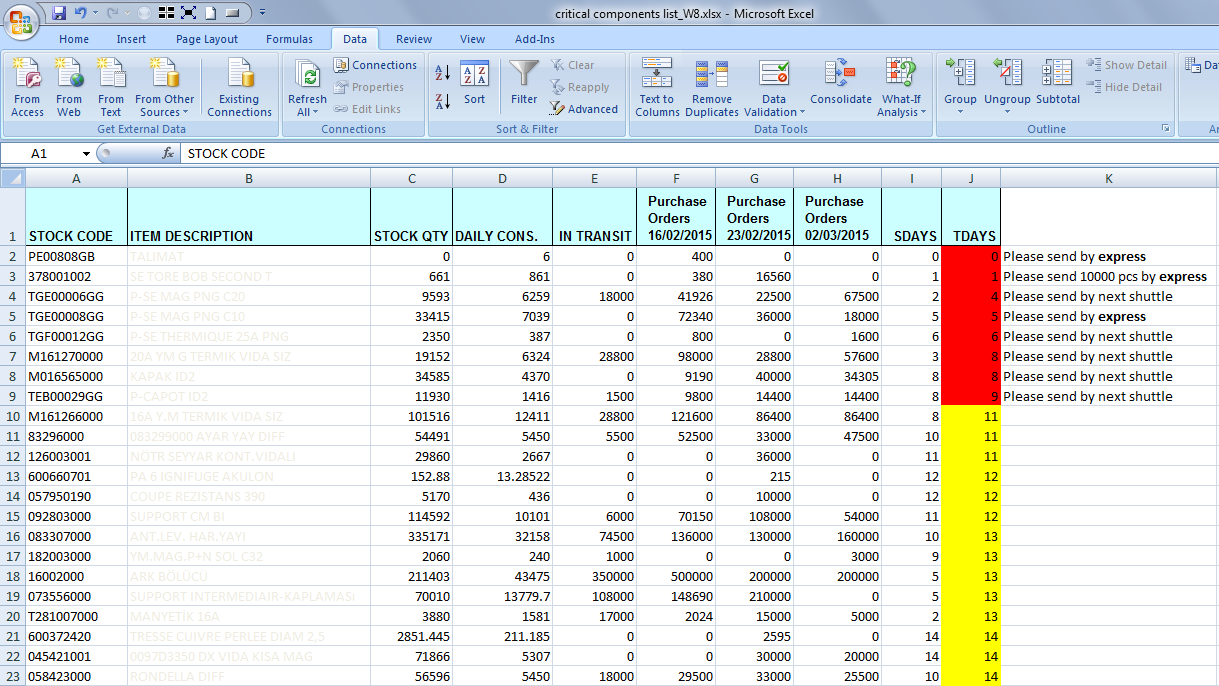

First, I gave points to the components on the critical component lists. We rate components according to the following criteria:

Tdays=(Stock Qty+transit Qty)/daily consumption Qty

Tdays up to 5 => 3 points

Tdays between 5 and 10 => 2 points

Tdays between 10 and 15 => 1 points

As you see, the most critical ones get the highest point. Then, we reduce gradually the points. You can rearrange points according to your needs. Most of our components supplied from Europe by truck and lead times are 20 days generally. I mean from lead time the interval between placing purchasing order and get delivered to our warehouse. Therefore, 5 days of stock on hand is very critical level. You can see the points beside each reference in the table below.

After giving these points to each week’s critical component list, we’ll prepare a new Excel sheet. We put stock codes on the first column. Then, we get each week’s points by VLOOK function to this table week by week. We have 16 pcs of critical component lists from week 40 to week 4. Then, we get total points of each stock code in the last column of the table. Finally, we sort the stock codes according to total points (sort by column T). This table shows how frequently which components fall in critical position.

This table is not the end, it’s beginning. The supplier and we have to do something for top components. We have to check their safety stock level. Since these components are frequently becoming critical, it’s better to increase their safety stock quantities. For instance, if we keep 7 days of safety stock for A class components, we may add let’s say +3 days to these components which are top of the list. Another approach is using express option efficiently. However, it brings additional cost comparing the truck shipments. The planners should push to the suppliers to improve their performance for these components. Besides this, the planner must pay special attention to these components while going through MRP screens. It’s better to have alternative suppliers such critical components. However, all we know some suppliers don’t have any alternative.

Forecasts and purchasing orders should be sent on time to the suppliers. If we expect any increase on demand, immediately these modifications should be sent to the supplier.